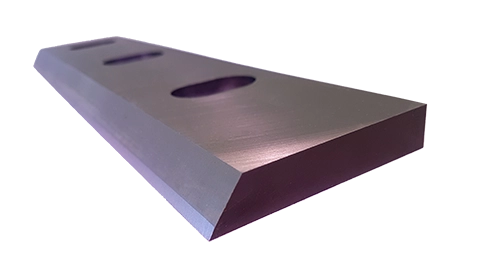

Heavy Duty Tough-Tipped Granulator Blades

If you regularly granulate hard or abrasive materials, your granulator blade’s edge wears off fast. To improve your cutting efficiency, we offer blades with a tough tip, offering up to 4x longer working life. The tips are attached to the blade, creating a complete mechanical and metallurgical bond.

These tips enhance the cutting edge’s hardness and wear resistance while maintaining a more ductile and shock-absorbent body. Our tough-tipped blades are especially suitable for environments where contamination occurs or where D2 blades are likely to suffer from chipping.

Applications where our customers use Tough-Tipped Granulator Blades

- Granulating hard plastics (e.g. HDPE, polycarbonate)

- Processing fibre-reinforced polymers or contaminated plastic waste

- Cutting rubber, cables, and other difficult materials

- Frequent blade wear or breakage is reducing uptime

- To extend maintenance intervals and improve cutting performance

Comparing D2 and Tough-Tipped Blades

| D2 Blades | Properties | Tipped Blades |

| ✔ | Wearability | ✔ |

| ✔ | Durability | ✔ |

| ✔ | Abrasion Resistance | ✔ |

| ✗ | Elevated Temperatures | ✔ |

| ✗ | Shatterproof | ✔ |

| ✗ | Heavy Duty Cutting | ✔ |

| ✗ | Acid Resistant | ✔ |

| ✗ | Corrosion Resistant | ✔ |

Advantages of Tough-Tipped Granulator Blades

Extended Blade Life

Reduced Downtime

Improved Consistency and Efficiency

Increased Resistance to Chipping and Cracking

Initially sceptical, but after our trial I was impressed when the blades lasted almost 4x longer than D2.

We’re now gradually swapping-out tipped blades onto all our granulators.

Repairing Tough Tipped Granulator Blades

We manufacture all our Tough Tipped Granulator Blades in our ISO 9001 accredited factory at Fernite of Sheffield. Using only high-quality steel from long-term suppliers and having strict control over operations, allows us to manufacture precision and durable OEM blades and knives every time.

Operating the UK’s #1 blade sharpening and regrinding service, out of both of our UK premises we’re able to provide technical support to our customers. We know, that our toughened blades retain their sharp edge for longer, and any chipping that occurs is typically minor. As a result, damage can often be repaired when sharpened, which removes less material and thereby extends both the efficiency and overall lifespan of the blades.

Significant cost savings can be achieved with this type of blade, especially those with a large cross-sectional area. One of the key advantages of these knives is their shatterproof nature, which helps protect the granulator machine from damage. Unlike solid tool steel blades which are prone to shatter upon impact, a tipped blade will twist, minimising the risk of catastrophic failure. This shatterproof quality is particularly valuable when processing materials that may be contaminated with foreign objects.

Contact us and get a technical support and a free precise quote with no obligations. Please compete the form on this page or Get in Touch.

Please contact Nick

to discuss any granulator needs.

Email: nick.wright@fernite.co.uk

Mobile: 07480 254837

WhatsApp: 07480 254837

1 Orgreave Road

Sheffield

S13 9LQ

United Kingdom

Available

Mon-Thu: 8.30am-5.00pm

Fri: 8.30am-3.45pm

Sat-Sun: Closed