High-Quality Granulator Blades for Plastics Recycling

Different materials wear blades differently

Recycling plastic scrap and size reduction are among the main applications of Granulator Blades. Using your machines continuously without a break, will eventually dull your granulator blades.

Even there, there is no general guideline on how often you should sharpen your granulator blades. When your blades get dull you may notice poorer cutting performance, granulator overheating, or increased noise levels during operations. Therefore, regularly inspect your blades for sharpness.

To keep optimise their cutting performance, granulator blades should be regularly sharpened and eventually replaced. Contact us to check whether your blade can still be sharpened. We provide a professional granulator blade sharpening service with natiowide collection & return of your blades. Regular sharpening scheduling improves efficiency and produces quality results.

Choose the blade material based on what you’re cutting

Material Type Recommended Blade Material

Soft plastics (PE, PP) Standard tool steel (D2) or Fernite tipped blades

Hard plastics (PC, PA) Hardened tool steel or coated blades

Abrasive plastics (glass-filled) Tungsten carbide or coated blades

Rubber High-impact tool steel

Blade Material Options

D2 tool steel – is a high wear resistant steel. Therefore, granulator blades made out of D2 would be durable. However, they are liable to chip if overloaded.

Tungsten Carbide Coated steel is extremely wear-resistant, but might become brittle if misused.

Fernite tough-tipped blades – proven to last 4x longer than D2

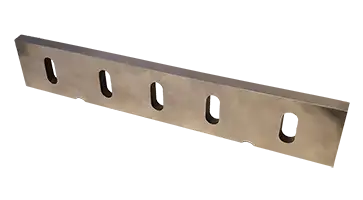

Blade Geometry

We manufacture all Granulator Blade types for plastic and rubber cutting in our Fernite of Sheffield certified factory and have a strong control over the quality. We make several types of blades that depend upon the geometry required by your application:

- Straight Blades are generally used for all purposes. These blades produce fast throughput and can be used for 24/7 jobs

- Hooked or Curved Blades are better for grabbing and slicing tougher materials like film or fiber

- Toothed Blades are used in fine-grinding granulators for consistent chip size

Granulator Blade Hardness

The hardness of granulator blades is a critical factor that affects their wear resistance, durability, and cutting performance. To avoid eneven wear, we advise you to match granulator blade hardness to screen hardness. If you are not sure what hardness to choose, please contact us and we will advice on the best one for your application

Different materials wear blades differently

Recycling plastic scrap and size reduction are among the main applications of Granulator Blades. Using your machines continuously without a break, will eventually dull your granulator blades.

Even there, there is no general guideline on how often you should sharpen your granulator blades. When your blades get dull you may notice poorer cutting performance, granulator overheating, or increased noise levels during operations. Therefore, regularly inspect your blades for sharpness.

To keep optimise their cutting performance, granulator blades should be regularly sharpened and eventually replaced. Contact us to check whether your blade can still be sharpened. We provide a professional granulator blade sharpening service with natiowide collection & return of your blades. Regular sharpening scheduling improves efficiency and produces quality results.

Choose the blade material based on what you’re cutting

Material Type Recommended Blade Material

Soft plastics (PE, PP) Standard tool steel (D2) or Fernite tipped blades

Hard plastics (PC, PA) Hardened tool steel or coated blades

Abrasive plastics (glass-filled) Tungsten carbide or coated blades

Rubber High-impact tool steel

Blade Material Options

D2 tool steel – is a high wear resistant steel. Therefore, granulator blades made out of D2 would be durable. However, they are liable to chip if overloaded.

Tungsten Carbide Coated steel is extremely wear-resistant, but might become brittle if misused.

Fernite tough-tipped blades – proven to last 4x longer than D2

Blade Geometry

We manufacture all Granulator Blade types for plastic and rubber cutting in our Fernite of Sheffield certified factory and have a strong control over the quality. We make several types of blades that depend upon the geometry required by your application:

- Straight Blades are generally used for all purposes. These blades produce fast throughput and can be used for 24/7 jobs

- Hooked or Curved Blades are better for grabbing and slicing tougher materials like film or fiber

- Toothed Blades are used in fine-grinding granulators for consistent chip size

Granulator Blade Hardness

The hardness of granulator blades is a critical factor that affects their wear resistance, durability, and cutting performance. To avoid eneven wear, we advise you to match granulator blade hardness to screen hardness. If you are not sure what hardness to choose, please contact us and we will advice on the best one for your application.

Please contact Nick

to discuss any granulator needs.

Email: nick.wright@fernite.co.uk

Mobile: 07480 254837

WhatsApp: 07480 254837

1 Orgreave Road

Sheffield

S13 9LQ

United Kingdom

Available

Mon-Thu: 8.30am-5.00pm

Fri: 8.30am-3.45pm

Sat-Sun: Closed