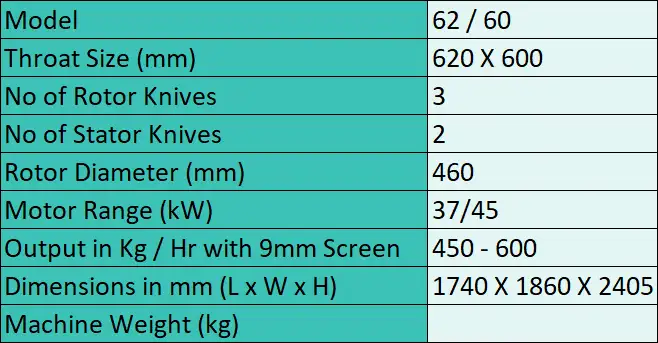

Blackfriars 62/60 Granulator System

Blackfriars 62/60 Granulator System

The Blackfriars 62/60 Granulator is a large medium/heavy duty granulator designed for today’s stringent requirements, producing consistently high quality granules.

As with all Blackfriars granulator machines, this unit has been designed with durability and reliability in mind.

TANGENTIAL FEED

The large throat opening is designed to accept large mouldings quickly and quietly with no fuss or throw-back due to the tangential feed.

LARGE ROTOR

The rotor with its three rows of shear cut adjustable knives is of heavy, but open construction. Running in large heavy duty bearings, outboard the cutting chamber and driven via a large flywheel, the rotor cuts against two rows of adjustable dead knives.

SAFETY

There is a rotor restraint with electrical interlock to ensure simple and safe knife changing. The whole machine is fully interlocked, yet readily accessible.

ACCESS

Access to the cutting chamber is made fast and easy with the electric opening system to both the feed hopper and the cradle. The cradle assembly with integral castors may be completely removed from the machine.

PNEUMATIC EXTRACTION

A pneumatic outlet chute is supplied for connection to an existing granule extraction system or to any system Blackfriars can supply with the machine.

QUIET OPERATION

No compromises have been made with sound attenuation. The result is a granulator that is both rugged and exceptionally quiet in operation.

The cutting chamber and drive are mounted on anti-vibration pads within the outer chassis . The whole machine is then totally enclosed within high quality sound attenuating panels and interlocked doors.

There is even an optional front feed hopper door (shown) for additional acoustic control.

The hopper, of heavy construction, may be hand fed as shown or ‘there is an additional feed opening to the top of the hopper for those long extrusions and mouldings, or for conveyor feeding.

The machine is fully wired with an integral motor and starter and requires the minimum of installation.

OPTIONAL EXTRAS

Additional Flywheel to Rotor (one as standard)

Rigid Sound Attenuating Door to feed opening

Temperature Sensing to Cutting Chamber with Digital Display

Pneumatic Granule Extraction Systems

SPARES & ACCESSORIES

Blackfriars offer a comprehensive range of OEM granulator blades, spares and accessories for our granulator machines and systems.

BLADE SHARPENING

As a member of the Fernite Group of companies we also offer the

#1 granulator blade re-sharpening service in the whole of the UK.