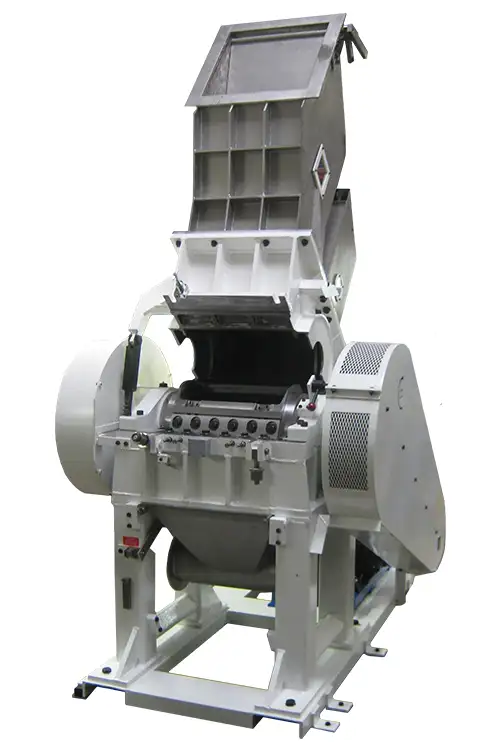

Blackfriars 525 Bale Granulator System

Blackfriars 525 Rubber Bale Granulator System

The Blackfriars 525 rubber bale granulator may be operated as a manual or automatic installation, producing a uniform granule at consistent rates. Mechanical assistance is fitted where required to ease access to the cutting chamber. A complete clean down of the machine for material changes is a simple task.

PERFORMANCE

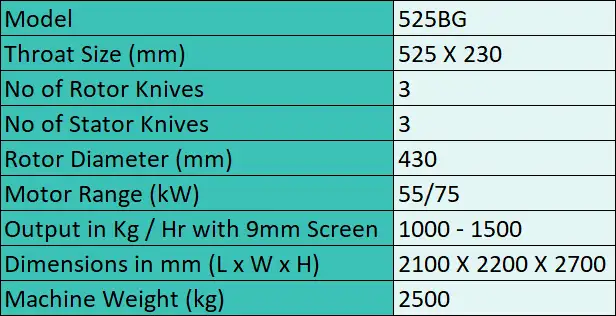

The Blackfriars 525 rubber bale granulator machine accepts complete 35kg bales of natural rubber and most grades of synthetic rubbers. In one pass it reduces these bales to granules. Granules in various sizes are obtainable down to a minimum size of between 6 – 8mm.

OUTPUT

This naturally depends upon the rubber being processed and the granule size. Typically, with many rubbers an output of 1,500 kg per hour is obtainable.

POWER REQUIREMENTS

The main driving motor is typically 75 kw. The granulator has a V-rope drive.

MACHINE CONSTRUCTION

The machine combines in a simple but ingenious way, several features including a rotor, storage chamber and a special knife configuration.

NOISE

Blackfriars supply complete sound attenuating enclosures.

SAFETY

The 525 rubber bale granulator incorporates the Blackfriars Scrulok Safety Switching System (with positive mechanical locking) which guards entry to the cutting chamber.

The whole machine is fully interlocked, yet readily accessible.

FEED

A conveyor for feeding the bales of rubber at a controlled rate is aavailable as an option.

EXTRACTION AND CONVEYING OF GRANULES

A pneumatic extraction and conveying system is available as an optional extra.

SPARES & ACCESSORIES

Blackfriars offer a comprehensive stock of spares and accessories for our granulator machines and systems

BLADE SHARPENING

As a member of the Fernite Group of companies we also offer the

UK’s #1 granulator blade re-sharpening service.