Blackfriars 320/150 Granulator System

Blackfriars 320/150 Granulator System

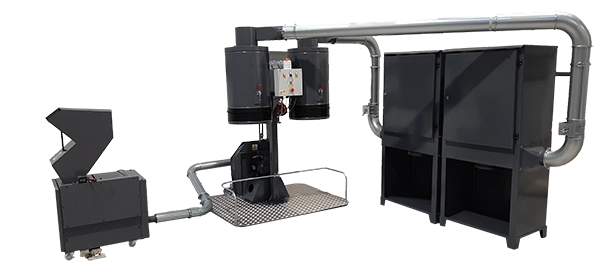

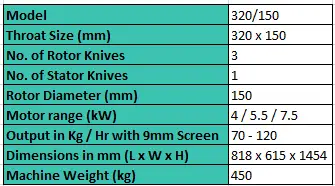

The Blackfriars 320/150 Granulator has been designed for inline, beside the press and offline granulating and recycling.

The large throat to narrow chassis relationship allows for installations in existing work areas. The large throat opening and powerful design means that for its size, the 320/150 granulator offers a performance which is second to none.

Easily manoeuvred due to its wheels, this machine is designed for ease of use and fast simple cleaning. As with all Blackfriars granulator systems, this unit has been designed with durability and reliability in mind.

THE CONSISTENT PERFORMER

The scissor cut knives found in the 320/150 granulator are manufactured from hardened steel, featuring adjustable rotor knives for a constant cutting circle and to allow re-sharpening time and time again. Knives are pre-set off the machine

- Large throat

- Minimal floor space

- Portable

- Scissor cut knives

- Constant cutting circle

- Minimal dust

- Low-noise

- Low energy consumption

- Easy access for cleaning

- No tools required for access

- Blade re-grinding service available

Additional options available

- Sound deadening

- Pneumatic extraction

- Airfall de-dusting

- Conveyor feed

- Robot feed

- Nip roll feed

- Extrusion feed

- Hot melt

- Temperature sensing

SOUND ATTENUATION

No compromises have been made with sound attenuation. The result is a granulator that is both rugged and exceptionally quiet in operation. The cutting chamber and drive are mounted on anti-vibration pads within the outer chassis. The whole machine is then totally enclosed within high quality sound attenuating panels and interlocked doors.

SPARES & ACCESSORIES

Blackfriars offer a comprehensive range of OEM granulator blades, spares and accessories for our granulator machines and systems.

BLADE SHARPENING

As a member of the Fernite Group of companies we are the

#1 granulator blade re-sharpening service in the whole of the UK.