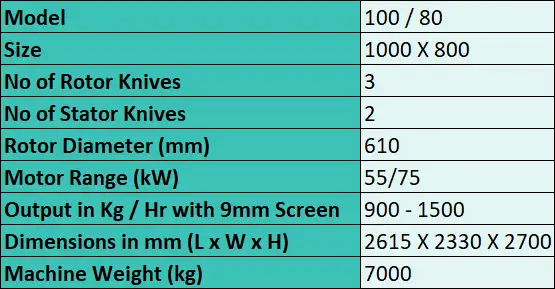

Blackfriars 100/80 Granulator System

Blackfriars 100/80 Granulator System

The Blackfriars 100/80 Granulator has been designed to handle large, bulky items in one operation, without the need for shredders or pre-breakers. As with all Blackfriars granulator machines this unit has been designed with durability and reliability in mind.

Typically the 100/80 will process:

Barrels, vehicle panels, bumpers, fuel tanks, large blow mouldings,

tanks & drums, large crates & boxes, rolls of skeletal waste, sheet.

The list of applications is endless and with the rear profile feed version extrusions of up to 6M in length can be safely fed into the 1000mm x 230mm profile feed opening. The feed is self regulating and ensures optimum throughput.

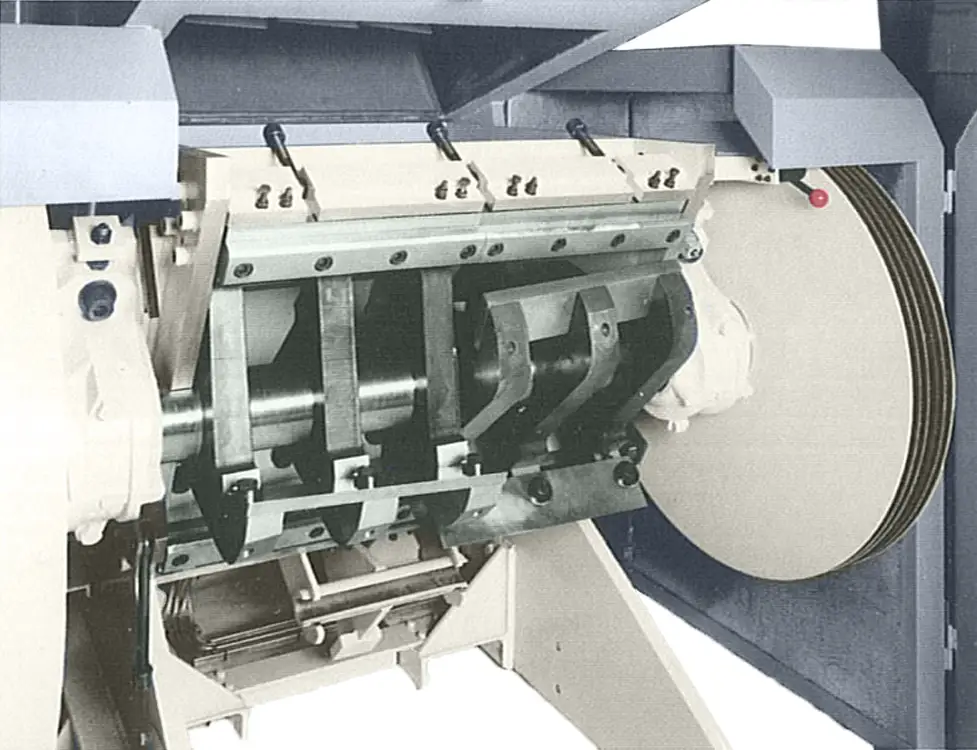

ROTOR

The special large diameter rotor and cutting chamber combination makes the 100/80 the most capable of granulators. The high torque combined with up to two large flywheels ensures that materials are granulated quietly and safely.

The rotor runs on two massive bearings which are located outside of the cutting chamber wall.

TANGENIAL FEED

The tangenial feed ensures that all materials to be granulated are pulled into the rotor without fear of bounce or flyback.

SAFETY

Despite being easy to use, access to the cutting chamber is made fast and simple. There is an electric actuator to open the feed hopper and the cradle. The cradle rolls freely away from the machine to further improve access for maintenance, the machine is fully safety interlocked and includes the Blackfriars Rotolok.

QUIET OPERATION

The whole machine and integral granule conveying fan is contained within its sound enclosure and feed hopper Combined with one of our acoustic controlled in-feed conveyors the 100/80 is total convenience.

As an option the 100/80 can be supplied without it’s acoustic enclosure. This is a useful cost saving if for example the machine is to be installed in an existing room and fed by conveyor through a wall.

KNIFE SETTING

The rotor has fully adjustable and pre-settable knives. This ensures a CONSTANT CUTTING CIRCLE and optimum performance throughout the life of the knives.

OPTIONS

The 100/80 granulator system can be supplied with numerous additional options, dependant on your specific process requirement. We would be interested to discuss your granulator issues and to investigate any special requirements or applications.

ACCESSORIES

A full range of accessories can be supplied including infeed conveyors, ferrous/non, ferrous metal detectors and separators, classifiers and dust extraction units as well as waste compactors.

SPARES & ACCESSORIES

Blackfriars offer a comprehensive range of OEM granulator blades, spares and accessories for our granulator machines and systems.

BLADE SHARPENING

As a member of the Fernite Group of companies we also offer the

UK’s #1 granulator blade re-sharpening service.